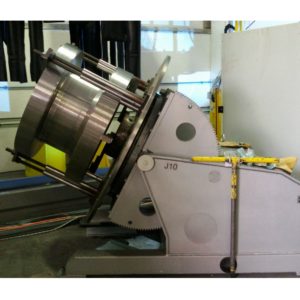

Hyundai HA006L robot used in welding overlay application.

In the province of Macerata, in the town of Urbisagia, Casarini Robotica has installed 2 robotic cladding systems.

The client company, Dafram S.p.a., founded in 1956 was the first company in Italy to build floating ball valves, which means that the company is listed in its sector as one of the most famous and competitive in the world.

The commissioned plants are each composed of a Hyundai HA006L anthropomorphic robot positioned on a motorized cursor on the ground runway, operating on two work stations consisting of two roto-tilting positioners of 4500 kg and 6500 kg.

Both the positioners and the cursor are motorized on the robot axis and therefore each plant controller manages 6 + 5 robot axes.

As regards the choice of the sealing part, an evolved high performance synergic inverter welding generator produced by EWM GMBH model Alpha Q 552 was used in combination with an OMI CHWM 11 refrigeration unit to allow very high processing duty cycles to be obtained.

Great satisfaction for Casarini Robotica and Dafram.

After a short period of training to assimilate the basic technical concepts to the use of a robotic system, both systems went into production to comply with an exceptional production order, in which the robots worked non-stop for about 12 months out of three. consecutive shifts seven days a week, without ever having a malfunction or breakdown that would preclude production downtime.

Hyundai robots have shown great resistance and reliability, thus creating the basis for the development of new commercial strategies in the area.